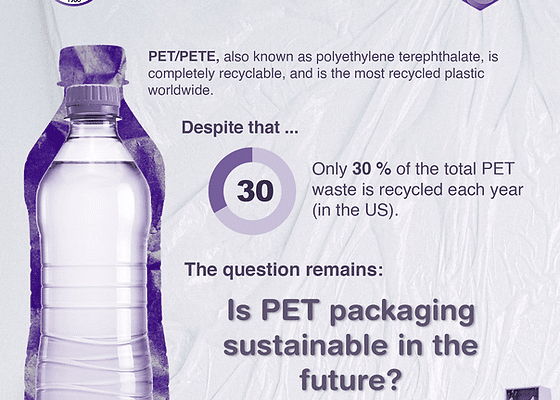

Polyethylene terephthalate (PET) is a versatile and widely used plastic material known for its durability, transparency, and lightweight nature. It is commonly used in the production of various packaging materials, including bottles, containers, and films. However, as concerns about environmental sustainability grow, it becomes crucial to explore the recycling potential of PET plastic. In this article, we will delve into the world of PET recycling, exploring the process, benefits, applications, and ways to improve the recycling of PET packaging.

1. What is Polyethylene Terephthalate (PET)?

Polyethylene terephthalate (PET) is a thermoplastic polymer resin that belongs to the polyester family. It is created through the combination of two monomers: terephthalic acid and ethylene glycol. The resulting PET resin possesses excellent properties such as high strength, clarity, and resistance to impact, making it an ideal choice for packaging applications.

PET’s unique characteristics have made it one of the most widely used plastics globally. It is commonly found in beverage bottles, food containers, textile fibers, and thermoformed packaging. Its popularity can be attributed to its cost-effectiveness, versatility, and ability to be recycled.

2. How is Polyethylene Terephthalate Recycled?

The recycling process for polyethylene terephthalate involves several key steps:

Step 1: Collection

The first step in PET recycling is the collection of post-consumer PET waste. This can be achieved through curbside recycling programs, drop-off centers, or specialized collection initiatives. It is essential to separate PET from other recyclables to maintain the quality of the recycled material.

Step 2: Sorting and Cleaning

Once collected, the PET waste undergoes sorting and cleaning processes. Advanced sorting technologies, such as near-infrared (NIR) spectroscopy, are utilized to separate PET from other plastic polymers. Additionally, contaminants like labels, caps, and residues are removed through washing and mechanical processes.

Step 3: Shredding and Pelletization

After cleaning, the PET waste is shredded into smaller pieces and then granulated into small pellets. This step increases the surface area of the material, facilitating the subsequent melting and remolding processes.

Step 4: Decontamination

To ensure the recycled PET meets strict quality standards, it undergoes a decontamination process. The pellets are heated in a controlled environment to eliminate any traces of impurities, such as residual chemicals or organic matter. This step is crucial, as it ensures the safety and suitability of the recycled PET for various applications, including food packaging.

Step 5: Reprocessing

The decontaminated PET pellets are now ready for reprocessing into new products. The pellets can be melted and extruded into fibers for textile applications, or they can be injection-molded or blow-molded into various shapes for packaging purposes. The reprocessed PET retains its original properties and can be used as a substitute for virgin PET resin in many applications.

3. Why Recycle PET Packaging?

Recycling PET packaging offers numerous environmental and economic benefits. Here are some key reasons why recycling PET is essential:

- Resource Conservation: Recycling PET reduces the demand for new raw materials, such as petroleum and natural gas, which are used in the production of virgin PET resin. By diverting PET waste from landfills and incineration, valuable resources can be conserved.

- Energy Savings: The production of recycled PET requires less energy compared to producing virgin PET. Studies have shown that recycling PET can save up to 84% of the energy required for manufacturing new PET resin. This energy savings translates into reduced greenhouse gas emissions and a smaller carbon footprint.

- Waste Reduction: PET packaging constitutes a significant portion of municipal solid waste. By recycling PET, the volume of waste sent to landfills can be substantially reduced, minimizing environmental pollution and the strain on waste management systems.

- Circular Economy: Recycling PET promotes the concept of a circular economy, where materials are kept in use for as long as possible, rather than being discarded after single-use. By closing the loop through recycling, PET packaging can be transformed into new products, extending its lifespan and reducing the need for virgin plastic production.

4. Classification and Cost of Recycled PET Materials

Recycled PET materials can be classified into different categories based on their level of purity and intended applications. These categories include:

- Clear PET Flakes: Clear PET flakes are obtained from post-consumer PET bottles and containers. They undergo thorough cleaning and decontamination processes to ensure high purity levels. Clear PET flakes are commonly used in the production of food-grade packaging, including beverage bottles and thermoformed trays.

- Colored PET Flakes: Colored PET flakes originate from colored or opaque PET bottles, such as thoseused for household cleaning products or cosmetics. These flakes undergo a similar cleaning and decontamination process as clear PET flakes. They are often used in the manufacturing of non-food-grade packaging, such as containers for personal care items or industrial products.

- Mixed Color PET Flakes: Mixed color PET flakes result from the recycling of PET bottles with different colors. While they may not meet the requirements for clear or colored applications, they can still be utilized in various non-food-grade packaging, such as polyester fibers, strapping, or sheet applications where aesthetics are less critical.

- Regrind: Regrind refers to ground-up PET material that has already been processed once. It is typically obtained from production waste or excess stock. Regrind may have slightly lower purity levels compared to flakes but can still be used in applications where strict color or clarity requirements are not essential.

The cost of recycled PET materials can vary depending on factors such as the level of purity, color, and market demand. Generally, clear PET flakes command a higher price due to their suitability for food-grade applications. Colored and mixed color flakes and regrind usually have lower costs, making them more attractive for non-food packaging purposes.

5. What Can PET Plastic Be Recycled Into?

PET plastic has excellent recyclability and can be transformed into various products through the recycling process. Some common examples include:

- New PET Packaging: Recycled PET can be used to create new packaging materials, such as bottles, jars, and containers. These products can serve a wide range of industries, including beverages, personal care, household products, and more.

- Polyester Fiber: Recycled PET can be processed into polyester fibers used in the textile industry. These fibers are utilized in the production of garments, carpets, upholstery, and other textile applications.

- Strapping and Sheet Applications: Mixed color PET flakes or regrind can be employed in the manufacturing of polyester strapping used for securing packages or as sheets for packaging protection.

- Building Materials: In some cases, recycled PET can be incorporated into construction materials. For example, PET fibers can be added to concrete to improve its strength and durability.

- Automotive Parts: Recycled PET can find application in the automotive industry, where it can be used in the production of various parts, such as carpets, seat fabrics, insulation, and under-the-hood components.

- Furniture and Home Goods: Recycled PET can be utilized in the manufacturing of furniture, cushions, pillows, and other home goods, offering a sustainable alternative to traditional materials.

6. How to Better Recycle PET Packaging?

To enhance the recycling of PET packaging, several key strategies can be implemented:

- Education and Awareness: Increasing public awareness about the importance of recycling and proper disposal of PET packaging is crucial. Educational campaigns can promote responsible recycling behaviors and encourage consumers to participate in recycling programs.

- Design for Recycling: Manufacturers should consider the recyclability of their PET packaging designs from the outset. By using mono-material structures, minimizing the use of additives, and ensuring labels and caps are easily separable, the recycling process becomes more efficient.

- Improving Collection Systems: Implementing effective and convenient collection systems, such as curbside recycling programs or drop-off centers, can encourage higher participation rates among consumers. Collaboration with local municipalities and waste management companies is essential to optimize collection infrastructure.

- Investment in Recycling Infrastructure: Governments, businesses, and organizations should invest in advanced recycling technologies and facilities. This includes upgrading sorting equipment, investing in decontamination systems, and expanding PET recycling capacity to meet the growing demand.

- Closing the Loop: Encouraging the use of recycled PET materials in the production of new packaging helps create a sustainable circular economy. Manufacturers can actively seek out suppliers that offer recycled PET options and incorporate them into their packaging supply chains.

7. What Recycled PET Products Can We Provide?

As a provider of recycled PET products, we are committed to offering sustainable and high-quality solutions. Our range of recycled PET products includes:

- Recycled PET Bottles: We offer a variety of recycled PET bottles suitable for various industries, including beverages, personal care, and household products. These bottles are manufactured using post-consumer PET waste, reducing the need for virgin plastic production.

- Recycled PET Containers: Our recycled PET containers provide a sustainable packaging option for food, cosmetics, and other consumer goods. These containers are designed with durability and functionality in mind while minimizing the environmental impact.

- Recycled PET Films: Our recycled PET films find application in flexible packaging, lamination, and labeling. These films offer excellent clarity, strength, and barrier properties, making them an ideal choice for a wide range of packaging requirements.

- Recycled PET Fibers: We supply recycled PET fibers that can be used in textile applications, including apparel, home textiles, and automotive fabrics. These fibers offer comparable quality and performance to virgin polyester fibers while reducing the reliance on fossil fuel-based materials.

- Customized Solutions: We understand the unique needs of our customers. Our team works closely with clients to develop customized solutions using recycled PET, tailored to specific product requirements and sustainability goals.

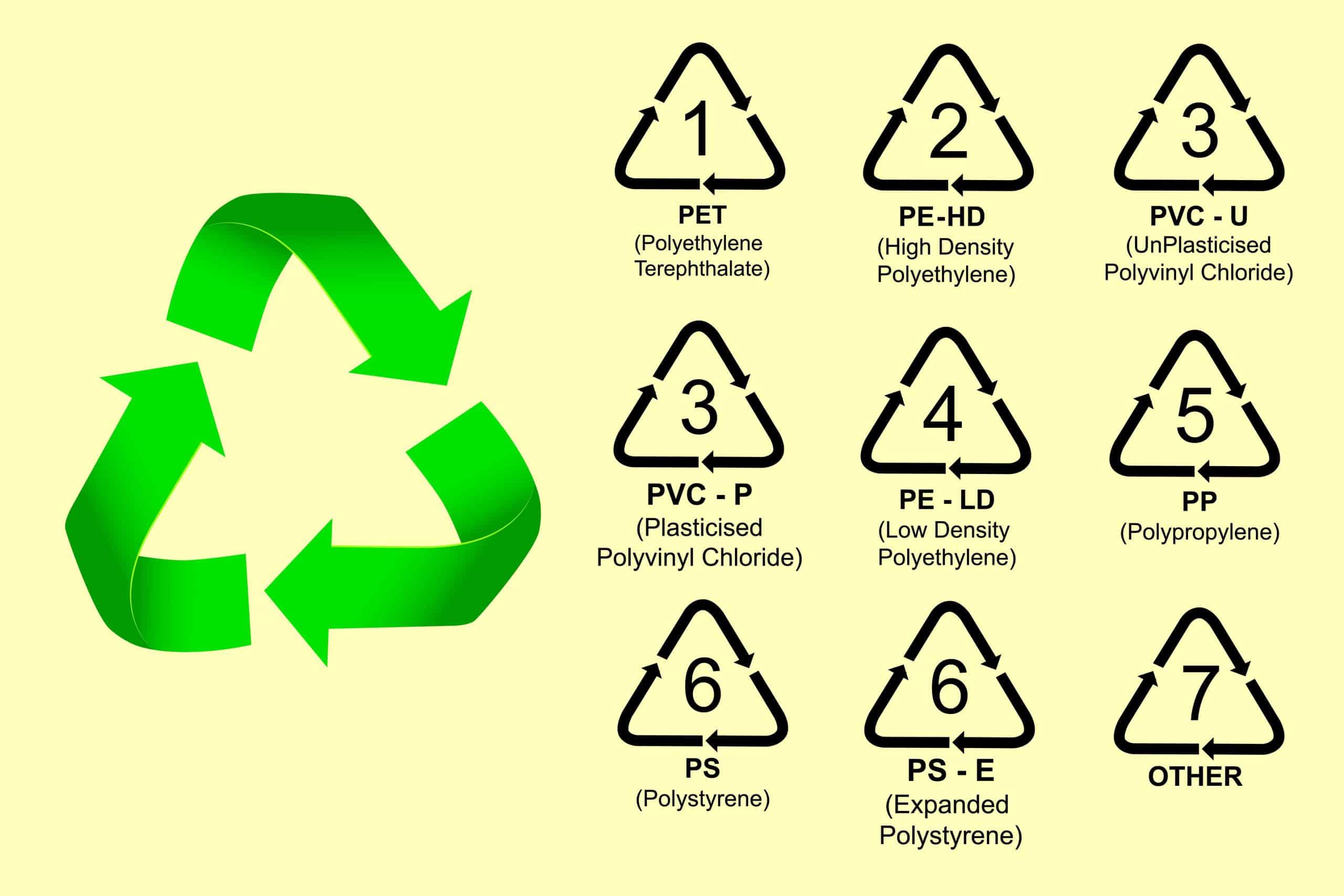

Can PET and PP Be Recycled Together?

PET (polyethylene terephthalate) and PP (polypropylene) are two distinct types of plastic with different chemical compositions. While both can be recycled individually, it is generally not recommended to recycle them together. Mixing PET and PP during the recycling process can lead to quality issues and affect the properties of the resulting recycled materials.

The recycling industry relies on efficient sorting processes to separate different types of plastics. This separation ensures that recycled materials maintain their integrity and can be used in appropriate applications. When PET and PP are mixed, it becomes challenging to achieve the required purity levels for each material.

However, it is worth noting that there are advanced technologies being developed to improve the recycling of mixed plastics. These technologies aim to enable the effective separation and processing of various plastic types, including PET and PP, from mixed waste streams. As recycling technologies evolve, there may be future possibilities for recycling PET and PP together.

Consult a Packaging Expert

If you have further questions or require specific guidance regarding PET packaging recycling or sustainable packaging solutions, we recommend consulting a packaging expert. Packaging experts possess in-depth knowledge of recycling processes, materials, and can provide tailored advice based on your unique requirements and objectives.

Conclusion

The recycling of PET packaging plays a crucial role in promoting environmental sustainability and reducing the reliance on virgin plastics. Through proper collection, sorting, cleaning, and reprocessing, PET waste can be transformed into valuable resources, minimizing waste generation and conserving resources. Various industries benefit from using recycled PET, ranging from packaging to textiles, automotive, and construction.

To maximize the recycling potential of PET packaging, it is essential to educate consumers, design packaging for recyclability, improve collection systems, invest in recycling infrastructure, and close the loop by incorporating recycled PET materials into new products. By working together and embracing sustainable practices, we can create a more circular and environmentally conscious future.